Consulting a site of ads for sale of used objects, I recently come across an old audio coil recorder, a saint-909 saint-909 magnetophone. The post was clear, the coil recorder was not working, but I still decided to buy it with the intent to fix it, given the modest price.

The SANYO MR-909 is a 4-track open coil recorder (two stereo channels for each direction of the ribbon) dating back to the late 1960s.

Here it is, just retired, the Sanyo MR-909 coil recorder: aesthetically it looks good. Of course, it has some small cosmetic defects, but what worries me most is the fact that nothing works, apart from the ignition light.

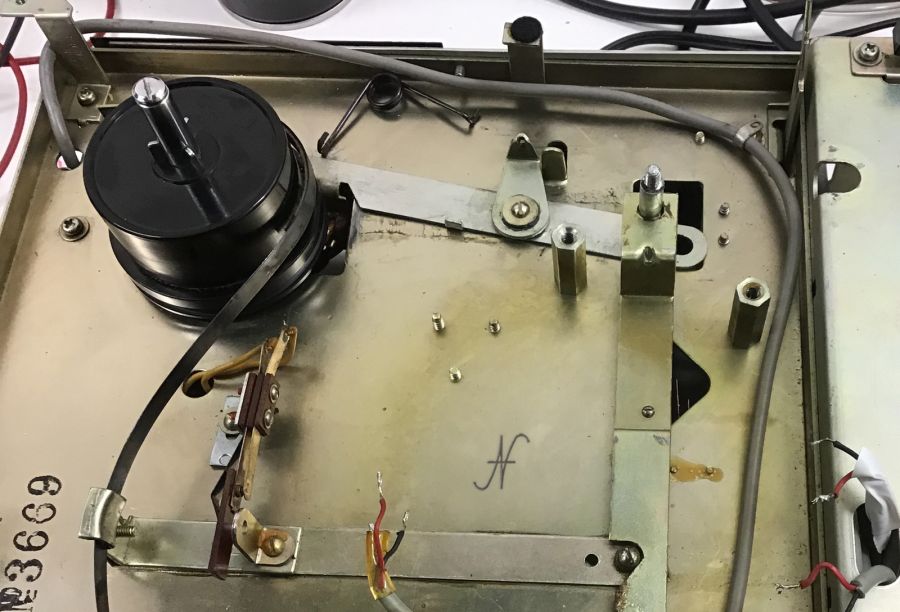

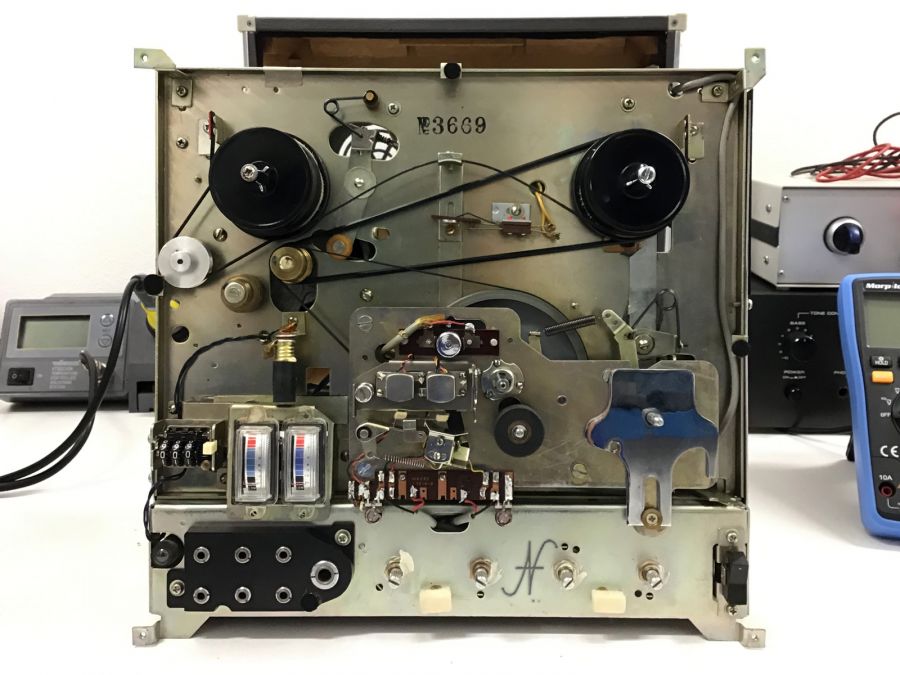

As soon as I disassembled, I started to try the recorder. I immediately noticed that the engine is spinning, while everything else is stationary. Not only are the belts missing, but several posts and pulleys are locked. Some pieces are also detached from their original position, which makes it even more difficult to find out where they were originally located.

Dapprima mi sono procurato su internet il manuale di servizio, il "service manual" del registratore a nastro. Non ho trovato proprio quello del Sanyo MR-909, ma bensì quello del Sanyo MR-929, registratore molto simile. Lo schema elettrico è già presente all'interno del mobile di legno. A chi servisse, condivido qui il service manual.

Sanyo MR-909 coil recorder, mechanics

The first part of the restoration of the SANYO MR-909 ribbon recorder concerns mechanics. It is very important to understand how the various mechanisms work and then proceed to restore them.

There are various functions and, to each one, a different mechanism is associated. In the service manual these functions are listed and there is also written how to regulate them.

Brake (brake mechanism): It is used to immobilize the two coils when the tape (recorder) is in the stop position. It consists of a metal strip that is pressed, through felt, on the rotating supports of the coils (feed reel base and takeup reel base).

Fast forward (fast wind mechanism): the heart of this mechanism is located in the support of the right coil (takeup reel base). The support is a clutch consisting of two wheels separated by a felt. The lower wheel is connected to the motor via a belt, while the upper wheel is connected to the coil. A system of levers adjusts the pressure of the lower wheel to the upper one, in this way, the torque of the motor is transferred to the coil in three modes:

- during rewinding the lower wheel presses very slightly on the upper one, which then is almost free to move;

- During the audio reproduction, the lower wheel presses a little more on the upper one, which therefore will have strength to wrap with variable speed, on the coil, the ribbon just reproduced (when the coil fills, increases the diameter of the ribbon turns, so it must rotate less quickly);

- Finally, during the fast advancement, the lower wheel strongly presses on the upper one, which therefore will have a lot of pair to wrap the ribbon quickly.

In my recorder, this mechanism was partially disassembled and required a lot of attention and adjustments.

Rewind (rewind): The support of the left coil is a double clutch. During the fast advancement and audio reproduction, the rotating support opposes a slight clutch, in order to keep the tape stretched. During the rewind, a pulley presses the belt on the lower wheel of the support which, through a felt, transmits the motion to the upper wheel connected to the coil. If the tape stopped, the clutch between the two wheels avoids the breakdown of the same. In addition to the pressure of the clutch, the pressure of the pulley should also be adjusted against the lower wheel of the support.

Audio playback (playback): the engine transmits power to a flywheel via a flat belt. The flywheel is connected to the capstan (the metal bevel that drags the tape), while the pinch roller (the plastic wheel) must press on the pinch roller with a strength of 650 to 950 grams. By means of a frequency meter and a sample tape (recorded with a frequency known through another recorder), it is possible to evaluate whether the playback speed is correct.

Felt pads: there are two felts that pressed the tape on the cancellation and playback / recording heads. Each felter must press about 20-25 grams on the respective head.

Counter: there are two belts and a series of pulleys to connect the left rotating support (feed reel base) with the counter.

The restoration of the mechanisms must also include accurate cleaning and lubrication of the Alberini. All the pulleys required accurate cleaning to remove the tracks of the old straps. The pins that rotate inside the bushings needed both a cleaning and a lubrication. Finally, I replaced the felt washers (they were present in the supports of the coils, in the flywheel group, capstan and pinch roller), with properly lubricated nylon washers.

Sanyo MR-909, the straps

I prefer to dedicate a chapter to the straps of the Sanyo MR-909 recorder because the size is crucial. Since the original straps were absent, I could not measure them and then buy new straps.

Sono partito da una misura "con lo spago". Da elettronico, non avevo spago in laboratorio, così ho ripiegato su un sottile cavo elettrico. Ho misurato con accuratezza il perimetro teorico di ciascuna cinghia, passando il cavetto attraverso le stesse pulegge che avrebbe percorso la cinghia. Ho poi ridotto di circa il 5% il perimetro misurato ed ho calcolato il diametro delle cinghie.

If for the square straps (the two of the counter) and for the flat one (that of the flywheel of the capstan) this procedure worked well, for the larger belt, the one that transmits the motion to the two coils, I had to cut and glue the belt purchased, shortening it to have a greater tension.

In the face of all these experiments, here is the list of straps to be purchased to be ready to restore a SANYO MR-909 and also a SANYO MR-929:

- Front of the counter (belt number 9 in the service manual on page 5): square thickness = 1mm, diameter = 70mm.

- Rear counter (belt number 6 in the service manual on page 5): square thickness = 1mm, diameter = 75mm.

- Flywheel flat (belt number 75 in the service manual on page 5): flat height = 6mm, diameter = 125mm.

- Belt of the supports of the coils (number 29 in the service manual on page 5): round thickness = 3mm, inner diameter 134mm, outer 140.

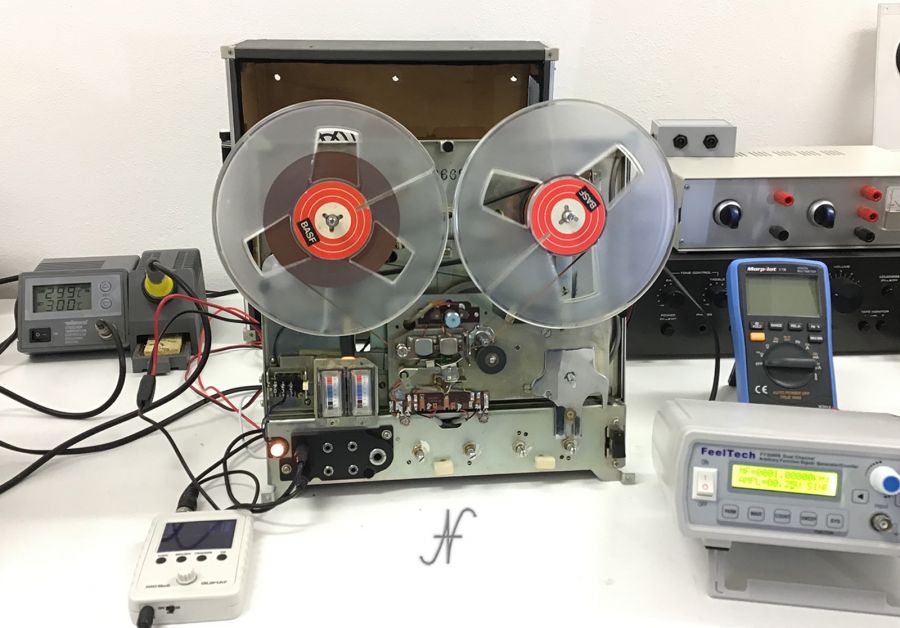

Sanyo MR-909 coil recorder, the test

Finally, after reassembling and calibrating all the reel to reel tape recorder (the coil recorder), I was able to try all the functions with the coils mounted on the supports. The most complicated functions to regulate are certainly the rewind and the fast advancement, which must be effective both with coils full of tape and empty.

The result was satisfactory, as all the mechanisms thus restored have regained the life they had in the past.

Unfortunately, the audio test did not give, at least at this stage, good results. Both audio channels are very weak and one of the two completely cuts the high frequencies.

For those interested in knowing how I solved: here is a article on the replacement of capacitors and other repairs I had to do to the Sanyo MR-909.

Cordial saludo...desde Colombia, estoy restaurando una idéntica, muy valioso su aporte , aunque no soy Electrónico, pues soy ING Mecánico amante de estos reproductores en mi tiempo libre , tengo una inquietud, UD tiene la referencia como SANYOgoo 909... Y la mía es 929..son las mismas...?

Cordial saludo..ya quedó resuelta mi duda con respecto a la referencia, UD lo aclaro muy bien al principio de su artículo, además encontré la respuesta a dos interrogantes que tenía,

La primera tenía que ver con el cambio de velocidad , ya que no encontraba ningún botón o perillas , cómo es lo más normal en las otras grabadoras, simplemente es retirar la camisa roscada del cabrestante e inmediatamente reduce la velocidad por ajuste en su diámetro ... genial.

La segunda no veía yo como podía rebobinar la cinta a la izquierda, si el rodillo no tenía transmisión directa con el motor, y resulta como UD lo aclaro el giro se hace por rozamiento de la correa con un rodillo auxiliar.

Estoy localizando las correas con las especificaciones que UD amablemente ha suministrado y listo.

Muchas gracias...

Arturo Colombia.

Hello! They are very similar, but please note that there are some small differences.

Hello Arturo, thank you very much for your comment. I am happy that my article was useful to you!