3CTR It is a complete control system for tunnel lifts. It is installed on three-armed equipment: tunnel tie-downs. The rib holders are essentially composed of two baskets for lifting people and a central arm to lift and mount the ribs, which are used to arm the tunnel vault.

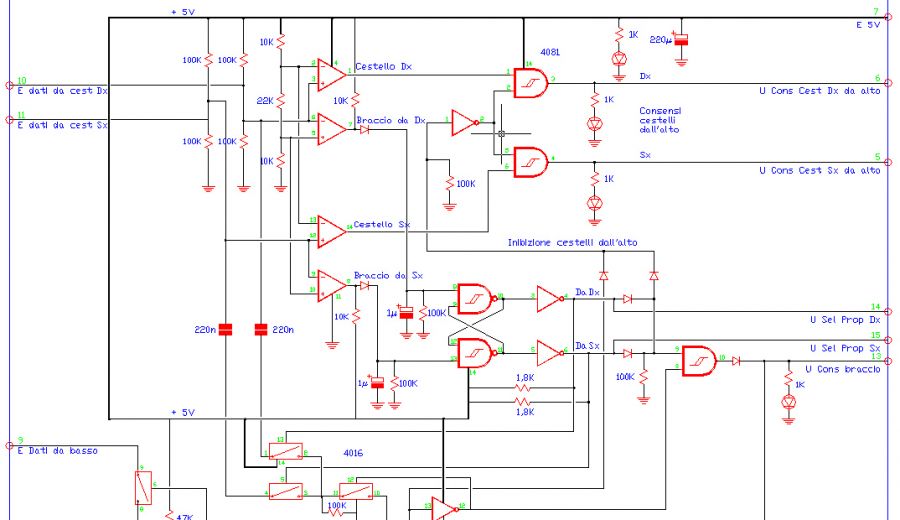

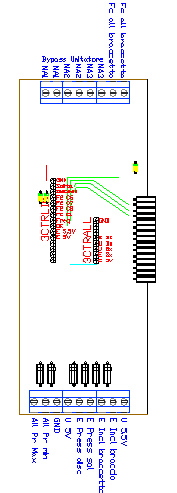

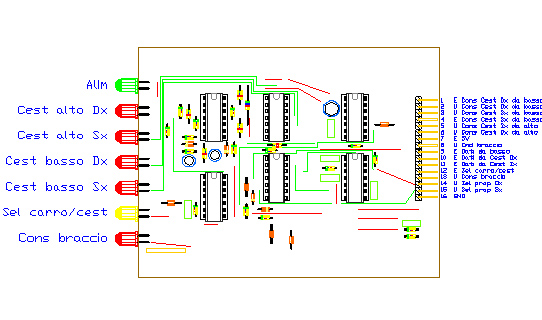

On each basket there are commands that allow operators to check the central arm of the ascentine. The proportional manipulators command proportional solenoids, which make the movements of the very fluid and also accurate lifting equipment. To operate a movement, you need to press the consent button first of all. In fact, this device serves to avoid movements not desired by the operators, who could compromise their safety.

The control arm controls are gathered in only two manipulators. There are two separate buttons for the opening and closing of the terminals that keep the hundred blocked. The buttons are separated from the rest of the commands to avoid errors from the operators, who would cause the hundreds of the hundred during assembly.

In addition, the emergency buttons are an important safety to lock the whole machine in case of emergency situations.

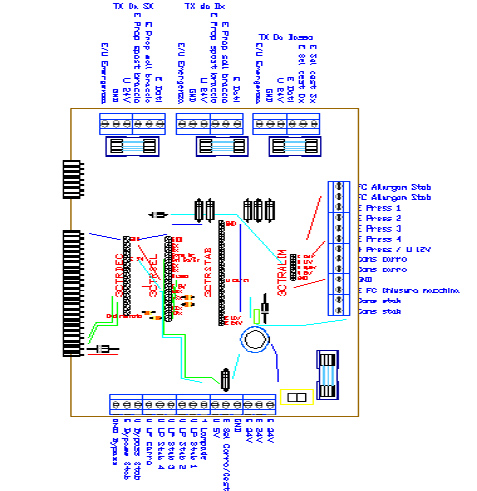

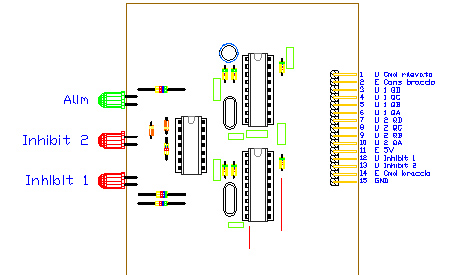

The 3CTR tunnel lift control system is equipped with safety functions that prevent movement in hazardous conditions. The moment limiter and load limiter (controlled by a microprocessor) also help operators lift the ribs safely.

The stabilization controller ensures that the tunnel column laying is perfectly stabilized before starting the rib assembly session.

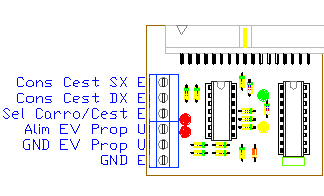

The control selector avoids incompatible simultaneous maneuvers, allowing operators to focus on the movements they are performing.

Control system for tunnel lifts 3CTR, the project

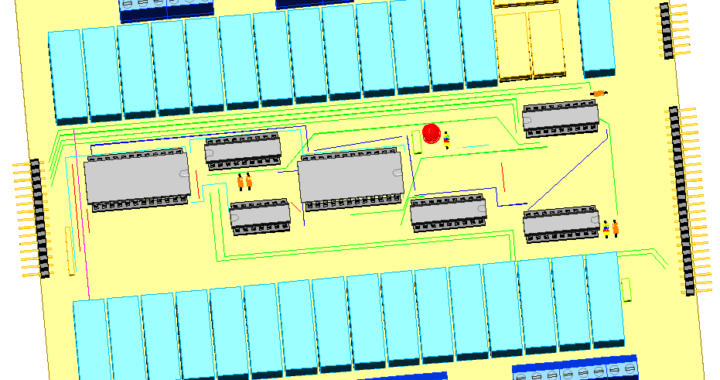

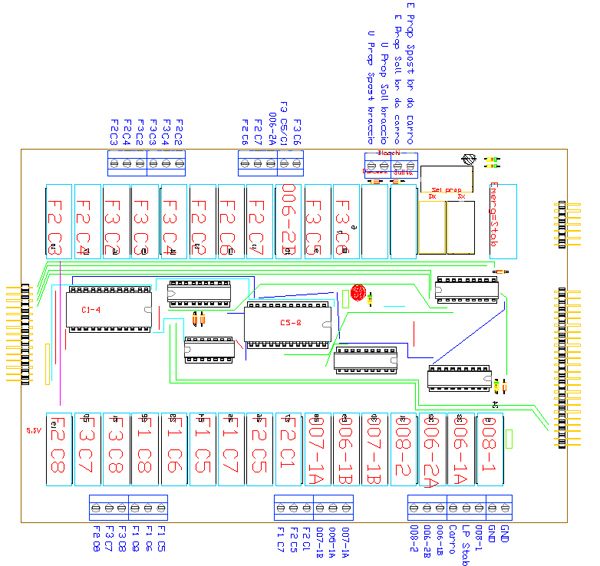

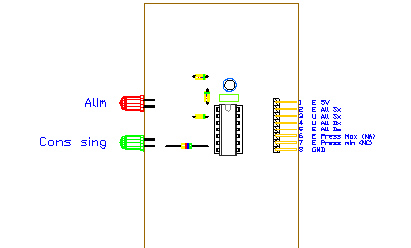

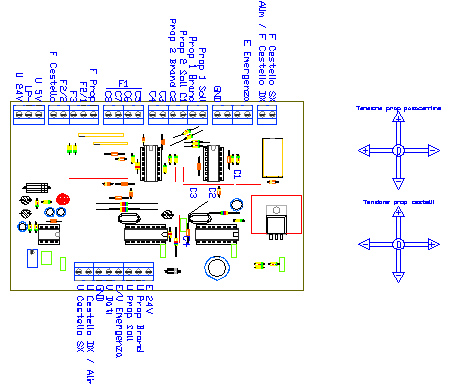

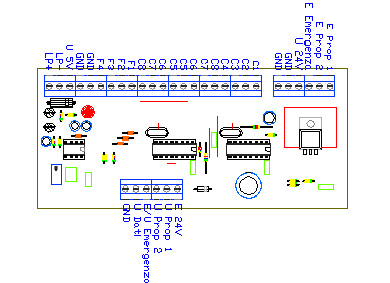

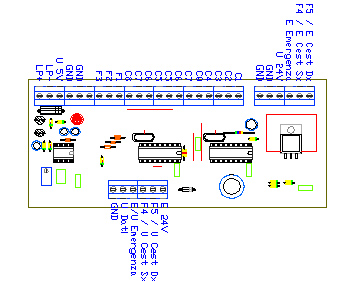

3CTR it is a complex project, composed of 16 different electronic boards, more than 40 integrated circuits and 550 discrete electronic components, which I made when I was 19 years old. The 3CTR tunnel lift control system controls over 40 solenoid valves (proportional and on/off). I took care of everything: the design of the wiring diagrams, the unraveling of the printed circuit boards, the realization of the prototypes, the firmware programming and also the programming of the configuration software that worked in the DOS environment.

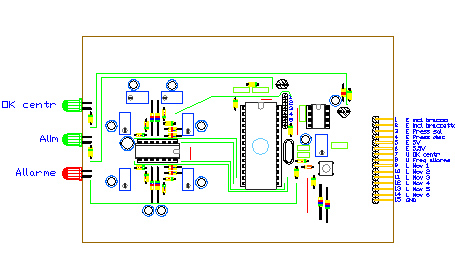

All the handling and control functions are performed by logic integrated circuits, while for the moment and area limiter (safety devices) I used a microprocessor, completely programmed in Assembler. The moment limiter was also developed on a separate circuit (CTR LIM project), which exploited the same program, but on an independent board.

3CTR, electronic board list

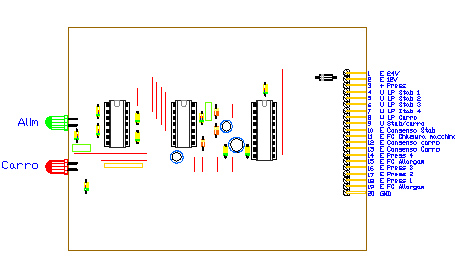

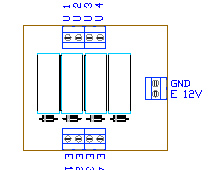

Relay motherboard, 3CTR R

PCB slot, motherboard, 3CTR RDX

PCB slot, motherboard, 3CTR RSX

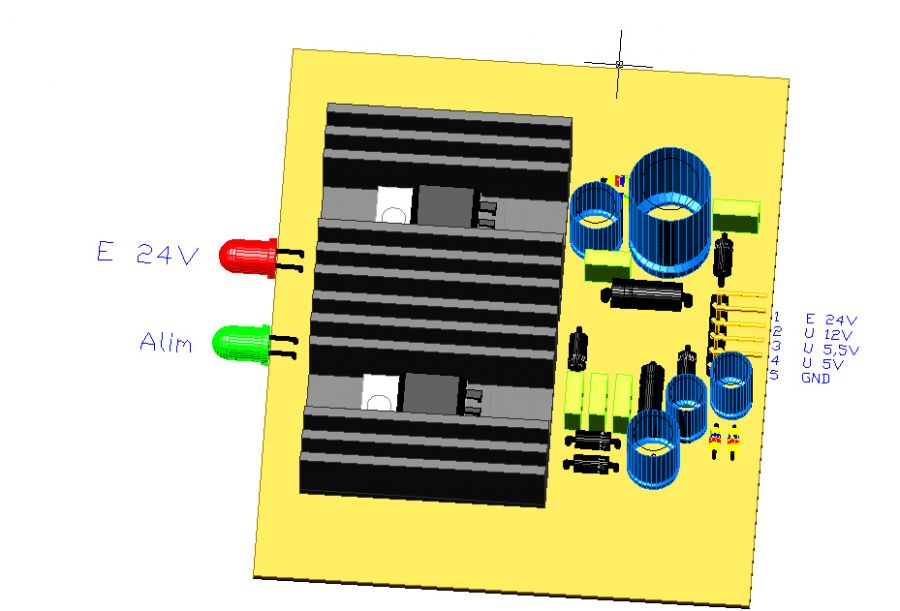

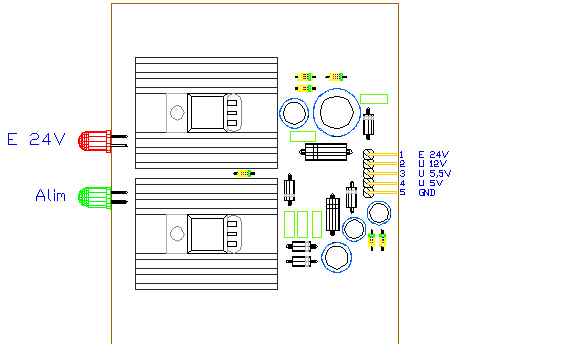

Power supply and filter, 3CTR ALIM

Mechanical Equipment Stabilization Controller, 3CTR STAB

Command transmitter selector, 3CTR SEL

Command decoder, 3CTR DEC

Rib Extender Controller, 3CTR ALL

Moment and area limiter, 3CTR LIM

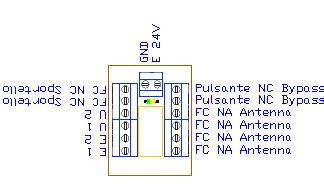

Command transmitter, 3CTR TC

Control transmitters, 3CTR TX1 and 3CTR TX2

Safety Data Sheet for Lifting People, 3CTR EBK

Arm solenoid valve amplifier, 3CTR EBF

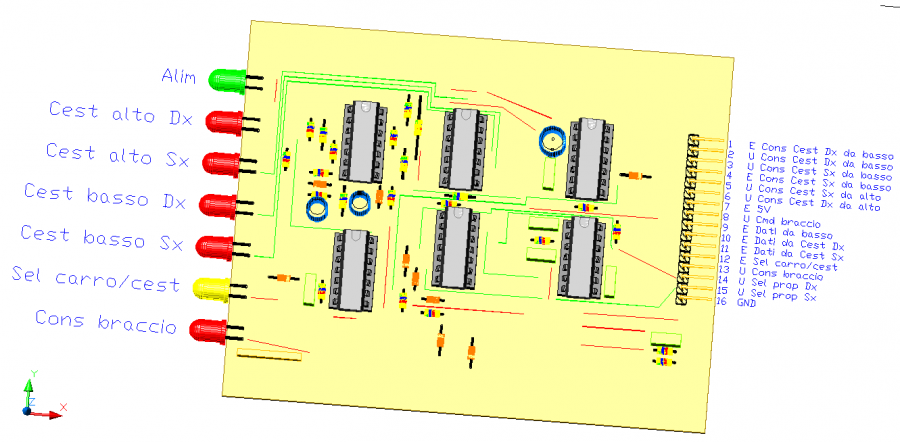

Processor for proportional solenoid valves, 3CTR CEST

Hour counter, 3CTR TM

Ecco, infine, una foto che rafficura una festa con il posacentine "decorato".

Project start: October 1996. Current state: discontinued.