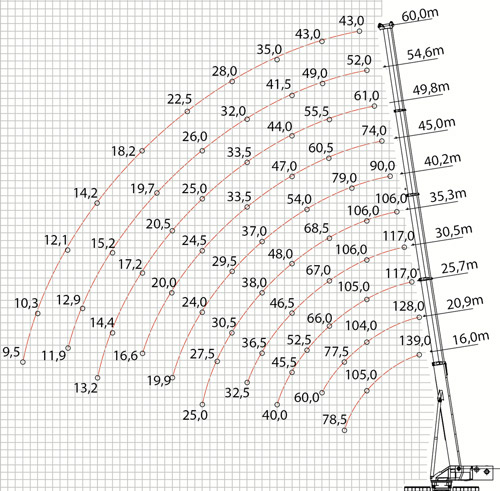

CTRLIM it is a moment limiter for cranes and telehandlers. The moment limiter stops the machine when the arm moment is greater than a set value.

The moment is expressed in Newton * meter (Nm) and measures the rotation effect caused by a force on a body. Imagine a load placed on top of the telescopic arm of a lifter: when the arm is tilted relative to the vertical, the weight would cause it to rotate downwards. Obviously the arm opposes an opposite force, so as to keep the weight in its position or, even, to lift it. When the moment is greater than the maximum allowed by the boom or crane as a whole, the crane may overturn or the arm may deform. For this reason, moment limiters are installed: they are safety devices that avoid the negative situations just exposed.

The moment limiter CTRLIM calculates the moment starting from:

- a tilt sensor (angle of inclination of the arm relative to the horizon);

- a telescopic arm length transducer;

- a pressure sensor on the boom lifting cylinder.

The moment limiter increases the safety of cranes and lifters, as it stops the equipment before the moment reaches the maximum value.

When the crane lifts a load, it can be safe for certain inclinations and for certain lengths of the arm. For example, the greater the extension of the arm, the greater the time, so the load becomes more dangerous. The more the arm is oriented horizontally, the more the moment increases.

Moment limiter CTRLIM, the project

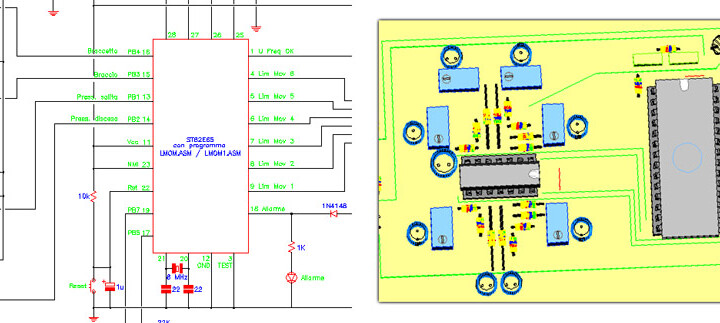

Electronic board, schematic design and unraveling of the mainboard printed circuit board, which has the following characteristics:

- central microprocessor;

- linear feeding stage;

- RS232 port for communication with the PC and configuration;

- N. 2 analog inputs for pressure sensors (4-20mA);

- N. 1 analog input for angle sensor (0-5V);

- N. 1 analog input for arm length sensor (0-5V);

- digital outputs to control the crane lock;

- digital output for acoustic and visual alarm signal;

- Status LED.

Microprocessor firmware: development of all the functions necessary to measure the various parameters, development of mathematical functions for complex operations, implementation of communication protocols, programming of functionalities.

Programming languages: Assembler, GWbasic.

Project startMay 1994. Current state: discontinued.